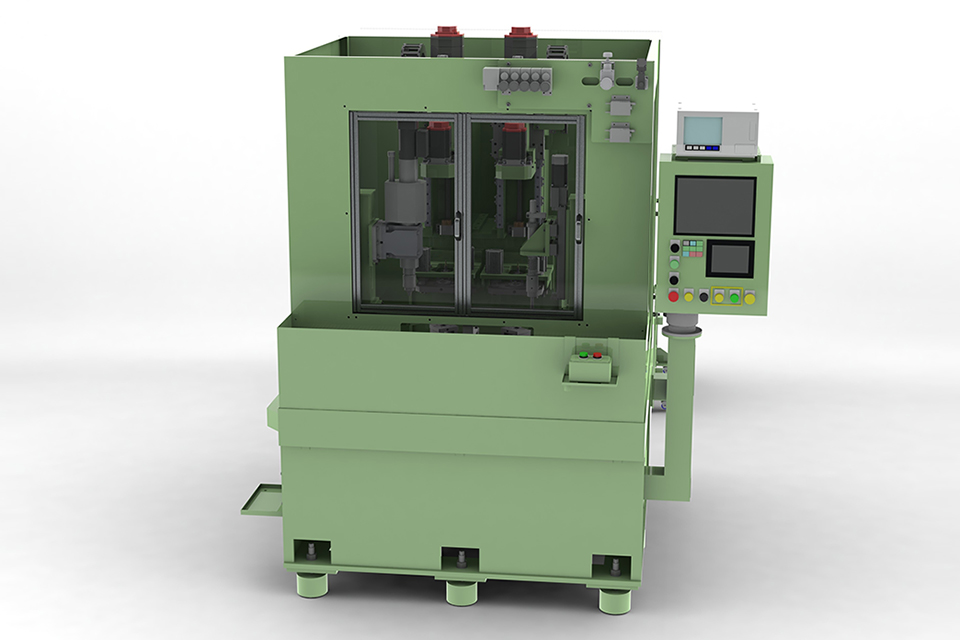

MR/MRN series

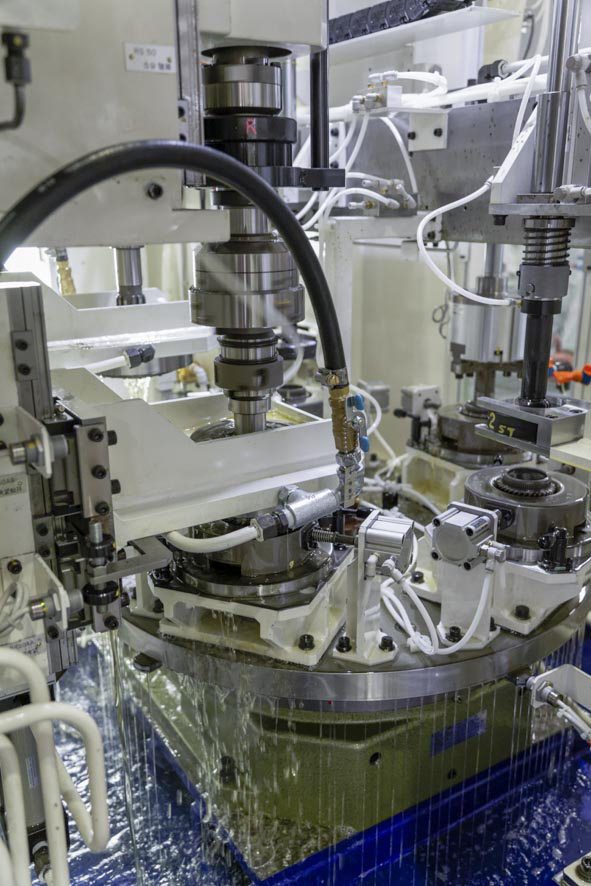

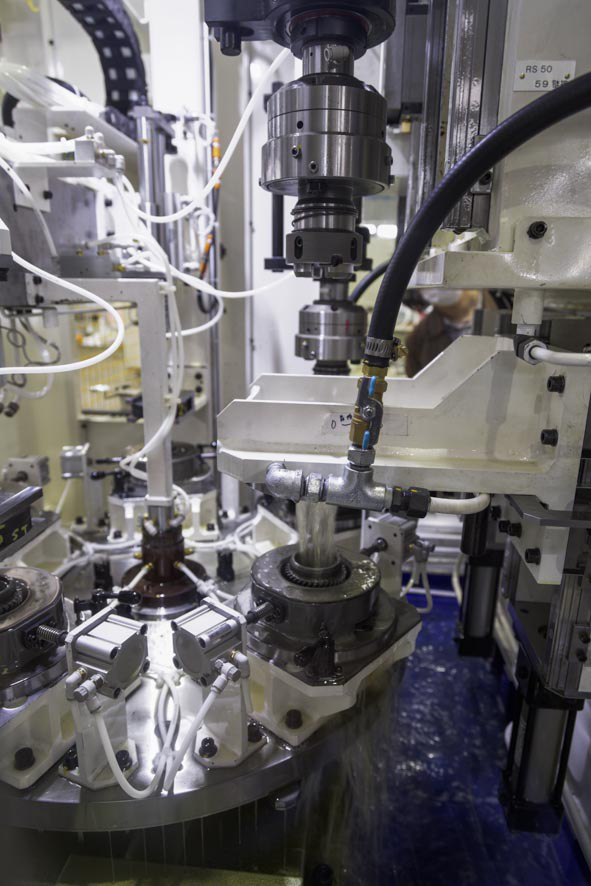

CNC machine model to realize energy-saving/space-saving, and support the efficiency of production line by high speed operation.

To adopt ball screw for spindle reciprocating, and achieve high speed change by servo motor.

To realize the high accuracy/high speed machining and the energy saving/space saving together, with many useful function.

Specification

No. of axis /Expansion method etc. is described at □

| Spec | Unit | MR-125-□ | MR/MRN-225-□ | MR/MRN-325-□ | MR/MRN-335-□ | MR/MRN-545-□ | MR/MRN-745-□ |

|---|---|---|---|---|---|---|---|

| Honing Capacity (Max. Dia.) | mm | φ25 | φ50 | φ75 | φ100 | φ150 | |

| Spindle Stroke (Max.) | mm | 250 | 350 | 450 | |||

| Spindle Rotation Speed (Max.) | min-1 | 2,000 | 1,000 | 800 | 800 | 400 | |

| Spindle Reciprocating Speed | m/min | 15 | 20 | 30 | 25 | ||

| Stone Expansion Method | Mecha. or Hyd. | Mecha. or Hyd. or Double Hyd. or Mecha.+Hyd. | |||||

| Spindle Motor for Rotating | Type | Servomotor | |||||

| kw | 0.75 | 1.0 | 2.7 | 4.5 | 5.5 | ||

| Spindle Motor for Reciprocating | kw | 2.5 | 2.7 | 5.5 | 5.5 | 14 | |

| Machine Overall Height* | mm | 2,200 | 2,600 | 2,700 | 2,900 | 3,500 | 4,000 |

| Floor Space (Width × Depth)* | mm | 1,000x1,500 | 1,100x1,600 | 1,200x1,800 | 1,400x2,100 | 3,000x2,500 | |

| Machine Weight (Approximate)* | kg | 2,000 | 3,000 | 3,500 | 4,000 | 5,000 | 10,000 |

*This is based on single axis machine with minimum constitution excluding any other equipment. (Subject to change according to required specification.)

Inquiry

All of our honing machines adopt the fully customized production system.

The model name is decided by machine model and basic spec. of machining diameter and max. stroke, but the detailed specification is customized to suit the production particular needs.

The inquiry about products is >>here

The model name is decided by machine model and basic spec. of machining diameter and max. stroke, but the detailed specification is customized to suit the production particular needs.

The inquiry about products is >>here

Customized Menus

- CNC Control

- Spindle Synchronizing Control

- Hydraulic Control

- Double Function

- Mecha. Expansion

- Hydraulic Expansion.

- Air Sizing

- Plug Sizing

- Auto. Master

- Spindle Shift

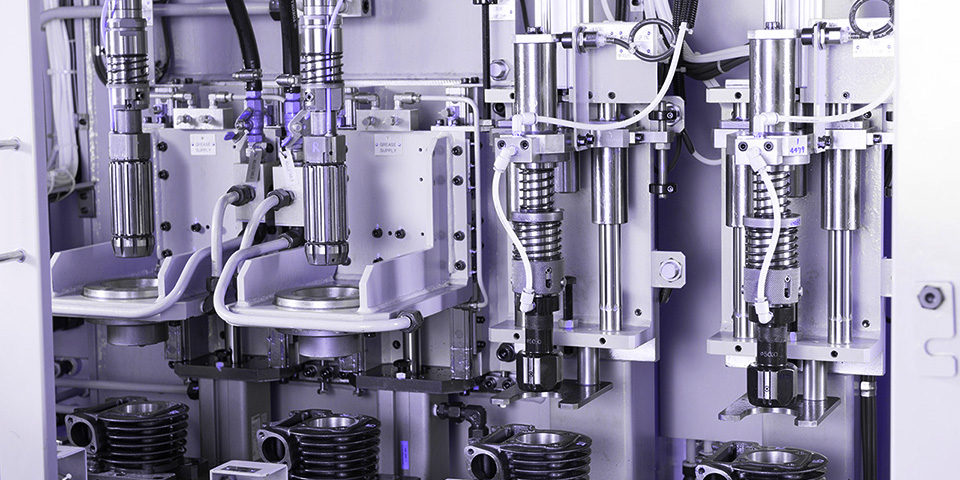

- Multiple Axis

- Variable Pitch between axes

- Floating Joint

- Cell type machine for random production

- ATC (Automatic Tool Changer)

- AJC (Automatic Jig Changer)

- Honing for Horizontal Bore

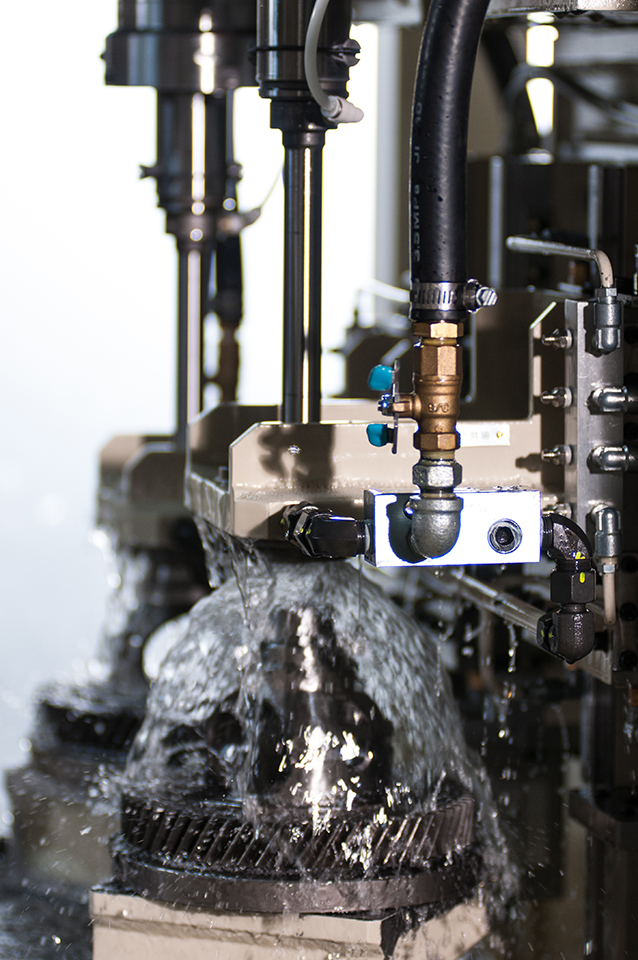

- Plateau Machining

- Multiple-layer machining

- Dummy Head

- Quenching/Hardening Treatment

- Measuring Equipment

- Measuring Result Feedback

- Model Identification

- Turn-over Unit for Coolant Disposal

- Movable Knock

- 3D Floating Jig

- Robot Transfer

- Tilting Jig

- Lift & Carry

- Slide & Carry

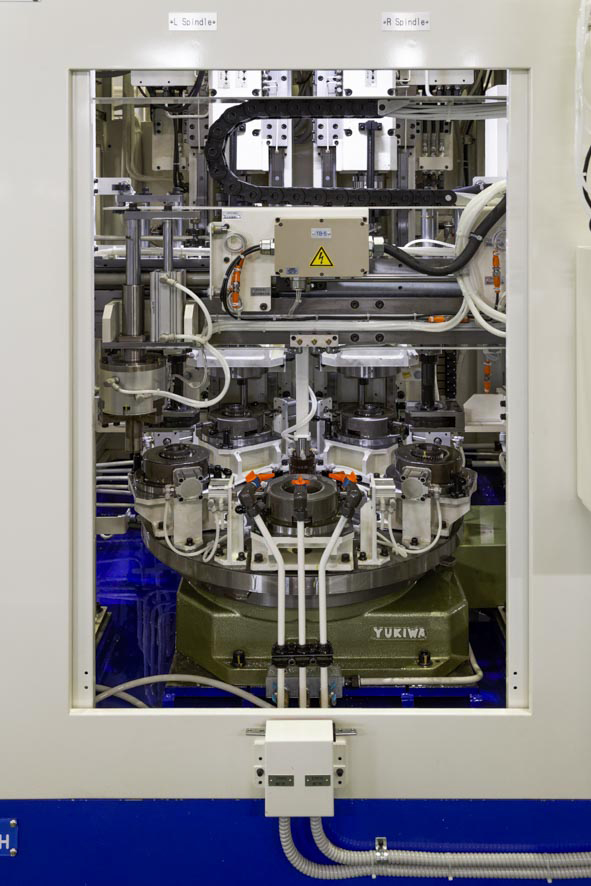

- Rotary Table

- Gantry Loader

- Conveyor Transfer

- Manipulator Transfer

- Pallet Transfer